30mm feed for 2-4 Strands

Dry cut Pelletizer

The 750-1 is a well-established machine designed in the 1980s we have sold hundreds of these units and we regularly see machines over twenty years old still in good condition, The machine is available as a free standing machine or an Integrated machine complete with cooling bath and dryer.

One customer with a wide selection of machines from various manufacturers told us it was the only machine that could cut his softest materials less than 40 durometer.

Our latest 750-1 has the same proven cutting design with today’s dual drive technology and safety features.

Laboratory Pelletising at low speeds

The 750-1 is often used for laboratory application that process 2-3 strands at low line speeds, using a 6 or 8 tooth rotor the line speed can run very slowly to cut precision pellets at low throughputs, ideal for small extrusion lines that only require small batches of pellets for testing, for this application we would recommend the 750-1 Integral unit or our Smaller BM15-HD

Precision cutting of extruded strands

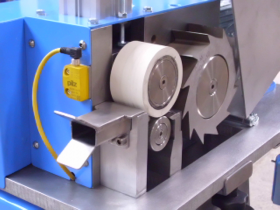

The clean, continuous cutting action of the multi-tooth helical rotor results in uniform pellet production. The rotor is mounted in an eccentric bearing housing, allowing close adjustment of rotor and stationary bed knife to produce perfect pellets.

Perfect for soft materials

The 750-1 has a straight feed table which does not allow the strands to be bent towards the cutter, this is essential for the production of soft materials. The distance between the nip point of the feed rolls and the cutting point is very close resulting in a cutting action that will cut materials that are very soft.

Easy clean for colour change applications

The overhung design of the machine allows the operator to remove the feed rolls and rotor from the shafts this can be achieved without the need of bearing removal. The machine is designed for easy clean down between colour changes. The overhung design of the machine allows the operator to remove the feed rolls and rotor from the shafts this can be achieved without the need of bearing removal.

Dual drive option

The 750-1 Pelletizer can be supplied as single drive with a set pellet length or dual drive the dual drive option allows the operator to change pellet lengths during production. Once the desired pellet length is selected the line speed can be adjusted and the pellet length will remain the same throughout the line speed range

Upper feed roll driven as standard

The upper feed roll is driven to allow maximum strand traction with special deep tooth gears this gear arrangement does not require any lubrication.

Safe no tool access

A solenoid locking safety switch is fitted to the main hood and discharge chute the switches locks the hood and discharge chute until the machine has come to a complete standstill. Once the machine has stopped the hood can be opened and the chute can be removed for easy cleaning.

Integrated sieve unit

The 750-1 strand Pelletizer can be fitted with a 100mm wide sieve unit the sieve can be fitted within the base of the machine to prevent any unwanted longs or fines contaminating the product.

Integrated cooling bath and Airknife dryer for compact low production

The 750-1 strand Pelletizer is also available as an Integral strand cooling and Pelletizing unit, this mobile system is suitable for laboratory and small production areas, the cutting chamber is mounted directly to the cooling bath, a small Airknife blower is used to dry the strands prior to Pelletising this system is ideal for small working areas. The 750-1 Integral is ideal for low line speed applications for low throughputs.

Complete extrusion line downstream equipment for higher production

The 750-1 free standing Pelletiser can be supplied as a complete line comprising of cooling bath, Suction dryer and Sieve unit please see our ancilary page for more information on our cooling baths and suction Airknifes.

Cooling bath

The cooling bath for the 750-1 is 200mm wide x 200mm deep and 2.5 meters long but we can manufacture to your dimensions, the cooling bath can be fitted with a plate heat exchanger and re-circulating system or a simple motorized valve to allow cool water into the bath.

Suction Airknife for strand drying

Our 800-50 suction dryer is a compact suction dryer which can be used to dry the strands prior to cutting this can be used as part of the complete extrusion line please see our ancilarry page for more details.

Throughput and power

Model Feed width Strands Kg/hr SG 1.05 KW RATING

750-1 30mm 4 106 1.1Kw with gears

750-1DD 30mm 4 106 1.1 Kw Rotor 0.375Kw feed rolls

Throughput shown is based on machine with 36 tooth rotor running at 60M per minute with 4 strands of SG1.05 the material specific gravity significantly changes the throughput of the machine. Please send us your requirements and we will work out your exact throughput.

Voltage

380/415v 3phase 50/60Hz

230/240V 1 phase 50/60Hz